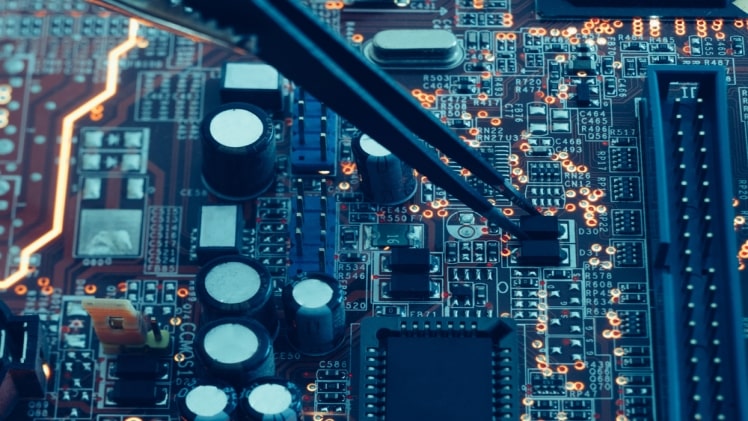

There are a number of manufacturers of printed circuit boards, but choosing the right one isn’t always easy. As soon as the PCB design has been developed, the PCB will be manufactured by the PCB manufacturer, which is usually a specialist manufacturer.

In PCB manufacturing can be made a lot easier by choosing the right company, however, choosing the wrong company can make the process a lot more difficult.

The process of researching the best PCB manufacturer is well worth your time and effort, but sometimes it is helpful to have some pointers to guide you towards making the right choice.

In terms of quality, the PCBs are excellent

Consideration should be given to the quality of the PCB manufacturer. Quality isn’t a specific concept with a specific meaning, and it is a bit abstract in its own right.

It is important to remember that PCB quality simply means that the board is delivered as requested and according to the drawing – without any errors.

A PCB’s quality is determined by a variety of factors, including:

- To determine the correct size of the board, measure it

- All holes were precisely positioned and drilled during drilling

- After passing a bare board test, the candidate has been hired

- Board warping should be minimal (although some can be the result of board design).

Having successfully secured an order, the quality of the final product should remain high and not deteriorate in the following days and weeks.

A PCB assembly or equipment manufacturer’s business cannot be compromised without a quality supplier. There is a possibility that other, non-competing companies may be able to provide information concerning the quality of their products in the future if they are using their products.

Meeting requirements within a reasonable time frame

It is imperative in the first instance to determine whether the manufacturer is capable of working according to your specifications.

It is important for me to know if they will be able to accept files in the formats that will be provided (normally this shouldn’t be an issue since PCB formats are generally standard), as well as produce the board according to specifications like the number of layers, type of PCB material, tolerances, and specific requirements.For each requirement to be met, a detailed checklist should be followed.

PCBs are expensive to manufacture

A successful project relies heavily on the CIST. Making a product successful requires reducing costs as much as possible, but one must also take care not to reduce the costs too far.

It is evident that the lowest price is a major factor in any decision. However, it has been said that we tend to forget the joy of low cost after we have recovered from the grief of poor quality.

It is important for the product’s quality to balance the price with its cost for the lowest price to be achieved.

Estimated time frames

Time may not be the most important factor in deciding whether or not to manufacture a PCB. While this is the case, PCB assembly companies usually have a specific deadline by which the boards need to be completed.

In order for you to be able to achieve these deadlines, it is imperative that you select a PCB manufacturer that will be able to meet them.

While it is useful to know that PCB manufacturers / suppliers can meet the agreed timescales, it is also useful to know that they can provide these boards quickly. Therefore, this usually comes at a higher price, and the turnaround time can sometimes result in more errors, especially if you request a quick turnaround.